This is part two of a three-part story. Again, too many pictures for one post, and a lot of explanation...three posts will make life easier.

To recap:

My brother, Dr. Lou Feurino, has just opened a private practice. He is a Psychiatrist, Psychotherapist, and working towards becoming an analyst as well. His practice specializes in combination treatment with talk therapy and medications, if needed, for help with problems relating to mood, anxiety, substance misuse, impulsivity, attention, interpersonal relationships, self-harm behaviors, and other issues. Dr. Feurino is trained in cognitive-behavioral, dialectic-behavioral, and psychodynamic psychotherapy, along with the use of medications and the detection of general medical problems that may mimic psychiatric disorders.

My brother needs a comfortable couch, but the cushion that came with his was more uncomfortable than the floor, so I made him a custom and extremely comfortable cushion.

Now on to how I made the nice, soft cushion cover:

|

| the finished cushion |

Now on to how I made the nice, soft cushion cover:

Like the rest of this story, nothing really went the way I had first intended for it to go. I was teaching myself how to do a cushion of this magnitude, and was researching daily to make sure I was giving my brother the best possible solution, all the while learning new techniques and tricks. This is why I love doing things that I have never done before, though there may be frustrating setbacks, the challenge and excitement of doing/learning something new is so fun to me.

For the cover's material, we had originally picked out a cotton fabric. However, as I continued my research I realized that this wasn't a very sturdy choice, and probably wouldn't hold up in the long run. So I ended up picking a sturdy upholstery-quality deep blue micro fiber suede (made of polyester) that my brother approved. I bought 5 yards of that material which, even on sale, was not cheap. I knew that working with this fabric was going to be a little difficult and tried my best through this process to not mess up with this fabric. I made sure that I had a little extra fabric, just in case, though at that price I wasn't going to get a whole bunch more (not even an extra yard).

I decided on making a boxed cushion cover, again this was something completely new to me. I understood it in theory (I'm the kind of person that can look at at finished piece and pretty much figure out how it was made) but I had to do a little research just to make sure I was on the right track.

Once I had figured out my plan, I had to make templates for the seven pieces that I had to cut. In my original plan my pieces were a little thinner because I didn't yet know what the size of my cushion would be. This is my original sketch (drawn before the cushion was made, thus why some measurements are missing):

However, when I took the original measurement of the cushion, I came up with 29" W x 82.5" H x 5.5" D. This meant that my original sketch was a bit off, so on I went to make the template based on these new measurements. The first pieces I made were the top and bottom, which I made 30" x 83.5" each, the next two pieces were the long sides, which I made 6.5" x 83.5" each, then one short side piece I made 30" x 6.5", and there were two pieces for the other short side (because it has a lapped zipper), which I made 30" x 3.5" and 30" x 6.5". Originally I had planned on having a .5" seam allowance, but it became apparent on my first fitting that I had allowed for too much depth on the cushion, and I had to take the seams in additionally to a total of a 1" seam allowance at each seam. This is because when I took the first measurement of the cushion, I allowed too much room for the edges' curves, and in reality the cushion ended up being more like 27"W x 82"H x 3"D.* Because I had already sewn the long sides I took in the seam like I mentioned above, but I hadn't yet sewn the short sides, so I was able to trim them down to 28" x 2" and 28" x 3.5".

*I had anticipated something like this happening, so I chose to err with bigger measurements rather than taking them as small as I thought they should be, just in case I was wrong, which is why my measurements kept changing. Now that I have done it, I know where I could have tightened my measurements a bit, but I still live by the saying MEASURE TWICE CUT ONCE! I swear I'm going to get that tattooed on my body somewhere.

When sewing, my first steps were to sew the top piece to both of the long sides, right sides facing each other. Then I sewed the bottom side on.

Inside of the cushion, I tucked the seams and sewed, giving a nice side detail to the cushion to keep the flaps of the seams out of the way.

I then started on the zippered end. The reason that I started with that end is because I could unzip the zipper and still flip the cover inside out, therefore allowing me to easily finish the sixth end, and not needing to leave out any seams. And it's easier to be able to work with my hands on both sides of the zipper to make sure everything is laying correctly. Zippers can be tricky. To sew the zipper, I first prepped the pieces by folding the raw edge over and sewing, then folding over a second time and sewing again, this way when the flap covering the zipper is lifted, no raw edges will be seen. I did this to both pieces, however I made a larger fold on the piece with the flap seeing as it would have to be long enough to cover the zipper. Then, with the zipper zipped up, I centered it on the non-flap piece, and pinned and sewed, moving the zipper to an unzipped position to get my machine to sew around it (which you totally understand if you have ever sewn a zipper). If you haven't sewn a zipper (and especially a lapped zipper), check out this quick little video to see what I'm talking about:

The fabric I used was thick, and the zipper head was huge, so I had a little more trouble than the girl in the video, but it wasn't horrible. I might have cursed a few times.

After sewing the lapped zipper, I now had a unit made up of the two pieces of fabric and the zipper, which I then sewed to the first short end of the cushion cover.

I then sewed the other short end of the cushion cover (with the zipper un-zipped so that I could turn the over inside- and "right side"-out.

The cover was now completed! The explanation seems a little more simple than doing felt, but that's only because again, I had never done anything to this magnitude before (especially not with such heavy fabric).

Stay tuned for the third and final post to this trilogy, where I'll show how I made the plastic cover and the custom detachable pillow and then I'll show you how it all came together. :)

If you, or anyone you know, would like to be in contact with Dr. Feurino, please email him at LouFeurinoMD@gmail.com.

|

| five yards of a nice deep blue micro fiber suede |

I decided on making a boxed cushion cover, again this was something completely new to me. I understood it in theory (I'm the kind of person that can look at at finished piece and pretty much figure out how it was made) but I had to do a little research just to make sure I was on the right track.

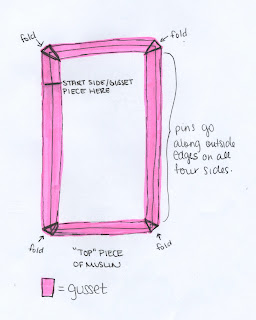

Once I had figured out my plan, I had to make templates for the seven pieces that I had to cut. In my original plan my pieces were a little thinner because I didn't yet know what the size of my cushion would be. This is my original sketch (drawn before the cushion was made, thus why some measurements are missing):

|

| my original plan of the cushion size and the seven pieces to cut (minus a few measurements) |

However, when I took the original measurement of the cushion, I came up with 29" W x 82.5" H x 5.5" D. This meant that my original sketch was a bit off, so on I went to make the template based on these new measurements. The first pieces I made were the top and bottom, which I made 30" x 83.5" each, the next two pieces were the long sides, which I made 6.5" x 83.5" each, then one short side piece I made 30" x 6.5", and there were two pieces for the other short side (because it has a lapped zipper), which I made 30" x 3.5" and 30" x 6.5". Originally I had planned on having a .5" seam allowance, but it became apparent on my first fitting that I had allowed for too much depth on the cushion, and I had to take the seams in additionally to a total of a 1" seam allowance at each seam. This is because when I took the first measurement of the cushion, I allowed too much room for the edges' curves, and in reality the cushion ended up being more like 27"W x 82"H x 3"D.* Because I had already sewn the long sides I took in the seam like I mentioned above, but I hadn't yet sewn the short sides, so I was able to trim them down to 28" x 2" and 28" x 3.5".

*I had anticipated something like this happening, so I chose to err with bigger measurements rather than taking them as small as I thought they should be, just in case I was wrong, which is why my measurements kept changing. Now that I have done it, I know where I could have tightened my measurements a bit, but I still live by the saying MEASURE TWICE CUT ONCE! I swear I'm going to get that tattooed on my body somewhere.

When sewing, my first steps were to sew the top piece to both of the long sides, right sides facing each other. Then I sewed the bottom side on.

|

| the sides sewn on, connecting the top and bottom pieces |

|

| the first fitting proved that I had to take in the fabric by using 1" seams on all sides |

|

| the second fitting was perfect and snug |

Inside of the cushion, I tucked the seams and sewed, giving a nice side detail to the cushion to keep the flaps of the seams out of the way.

|

| detail of the long sides, the stitching makes the cover look fancy |

I then started on the zippered end. The reason that I started with that end is because I could unzip the zipper and still flip the cover inside out, therefore allowing me to easily finish the sixth end, and not needing to leave out any seams. And it's easier to be able to work with my hands on both sides of the zipper to make sure everything is laying correctly. Zippers can be tricky. To sew the zipper, I first prepped the pieces by folding the raw edge over and sewing, then folding over a second time and sewing again, this way when the flap covering the zipper is lifted, no raw edges will be seen. I did this to both pieces, however I made a larger fold on the piece with the flap seeing as it would have to be long enough to cover the zipper. Then, with the zipper zipped up, I centered it on the non-flap piece, and pinned and sewed, moving the zipper to an unzipped position to get my machine to sew around it (which you totally understand if you have ever sewn a zipper). If you haven't sewn a zipper (and especially a lapped zipper), check out this quick little video to see what I'm talking about:

The fabric I used was thick, and the zipper head was huge, so I had a little more trouble than the girl in the video, but it wasn't horrible. I might have cursed a few times.

After sewing the lapped zipper, I now had a unit made up of the two pieces of fabric and the zipper, which I then sewed to the first short end of the cushion cover.

|

| lapped zipper |

|

| showing the opening and function of the zipper |

I then sewed the other short end of the cushion cover (with the zipper un-zipped so that I could turn the over inside- and "right side"-out.

The cover was now completed! The explanation seems a little more simple than doing felt, but that's only because again, I had never done anything to this magnitude before (especially not with such heavy fabric).

Stay tuned for the third and final post to this trilogy, where I'll show how I made the plastic cover and the custom detachable pillow and then I'll show you how it all came together. :)

If you, or anyone you know, would like to be in contact with Dr. Feurino, please email him at LouFeurinoMD@gmail.com.